DIAMOND WIRE SAWS

The Diamond Wire Saw CS series is a compact diamond wire saw that is ideal for research and development applications. Since the impact of cutting is low and the cutting area is small, it is possible to cut brittle and precious samples, samples for electron microscopy, small samples for measurement and observation, and medium-sized samples of about 100mm with no burr or chipping. Type CS-411 is equipped with an automatic slicing table to easily cut out wafers with minimal burr and chipping. Both wet and dry cutting is possible.

Diamond Wire Saws

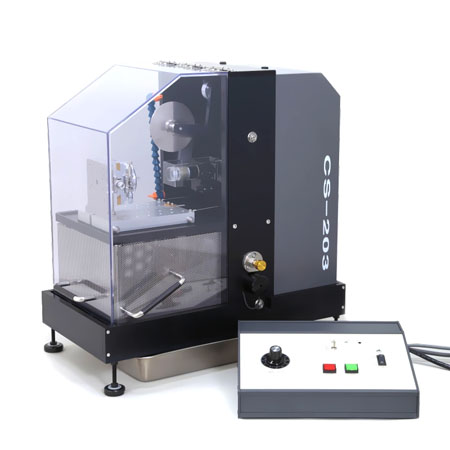

| CS-203 |

|

Size | W441mm×D563mm×H594mm (W17.3″×D22.1″×H23.3″) |

| Weight | 25kg (55.1lbs) | |

| Wire | Diamond Wire 37m (121.3′) | |

| Wire Speed | 150mm/min (5.9″/min) | |

| Control Panel | Analog Controller | |

| Work Size | W150mm×D150mm×H150mm (W5.9″×D5.9″×H5.9″) |

|

| Motor Type | 3/8HP (283W) 2500rpm DC motor |

|

| Power Input | AC 100V | |

| Since cutting is done by reciprocating wire motion, it can handle larger specimens than the Cartridge type. There is no detectable heat generation during cutting, and there is almost no change in the quality of the sample. Almost no burrs are generated, even for thin-walled tubes, because it is possible to cut with little burrs. There is almost no chipping when cutting glass, crystal, semiconductors, jewelry, etc. It is possible to cut very fragile semiconductors or pre-fired ceramic materials. It does not damage expensive crystals (SiC, Si3N4, AIN, GGG, LN, LT, etc.). It is possible to cut materials reinforced with hard fibers without fluffing. Similarly, materials with ceramic-coated surfaces can be cut without cracking. |

||

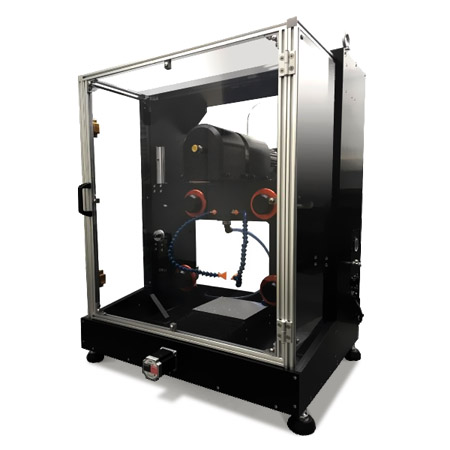

| CS-411 |

|

Size | W752mm×D589mm×H955mm (W29.6″×D23.1″×H37.5″) |

| Weight | 150kg (330.6lbs) | |

| Wire | Diamond Wire 37m (121.3′) | |

| Wire Speed | 150mm/min (5.9″/min) | |

| Control Panel | Program Controller | |

| Work Size | W200mm×D200mm×H150mm (W7.8″×D7.8″×H5.9″) |

|

| Motor Type | 3/8HP (283W) 2500rpm DC motor |

|

| Power Input | AC 100V | |

| Since cutting is done by reciprocating wire motion, it can handle larger specimens than the Cartridge type. Both wet and dry cutting is possible. There is no detectable heat generation during cutting, and there is almost no change in the quality of the sample. With the keypad controller, various settings such as cutting width, cutting frequency, cutting depth, wire drop speed, deflection angle, etc. can be made considering the wire diameter. Compared to type CS-203 diamond wire saw, it is possible to cut a larger sample size. The degree of freedom of various options is higher than CS-203 in addition to the standard specification jig. |

||

Diamond Wire

|

Model | Core Diameter | Diamond Size | Cutting Width |

| 12PLAU | 120μm | 10μm to 20μm | <150μm | |

| 17GNPU | 170μm | 22μm to 36μm | <250μm | |

| 30GNPU | 300μm | 22μm to 36μm | <400μm | |

| This is a fixed abrasive wire with diamond abrasive grains electrodeposited around the core wire. Higher cutting accuracy and faster cutting time are realized. Through our thorough quality control, we are able to supply products of high quality and stable performance at low prices. We can meet various requests with many types of diamond wire with different wire diameters, abrasive grain sizes and grain densities. |

||||

Expendables

| Model | Feature |

|

Surfactant can remove cutting chips by penetrating the interstices between wire and sample. It is important part of the comfortable severing work. To optimize it and increase your productivity we provide cutting fluid with surfactant. |

| Cutting Fluid | |

|

A porous ceramic plate ideal for bonding samples with wax. Used for cutting with a precision blade saw or diamond wire saw. |

| Porous Plate | |

|

The perfect adhesive for working with diamond wire saw. High adhesive strength to withstand cutting. Can be washed with acetone and methyl ethyl ketone. Acetone: C3H6O Methyl Ethyl Ketone: CH3COC2H5 |

| Phthalic Glue |

| Thank you for reading this to the end. |

Musashino Denshi, INC.

1-17-18 kichijoji higashi, Musashino, Tokyo, 180-0002 Japan

E-mail: info@musashino-denshi.co.jp

Copyrights © 2021 Musashino Denshi, INC. All Rights Reserved.