LAPPING SYSTEM

Automatic and manual lapping machines and accessories. This series of lapping machines offers high quality, high precision, efficient and reasonably priced leveling, grinding, lapping and polishing.There are four sizes of the base machine, all offering high precision, 150, 200, 300 and 400. An entire range of leveling, grinding, lapping and polishing plates are available, using the diamond lapping principle in conjunction with composite plate technology.The diamond feed is precisely controlled with the use of an driven diamond slurry feed system. An important feature of the Musashino Denshi lapping system is the variety of sample holders available.

Precision Lapping Machines

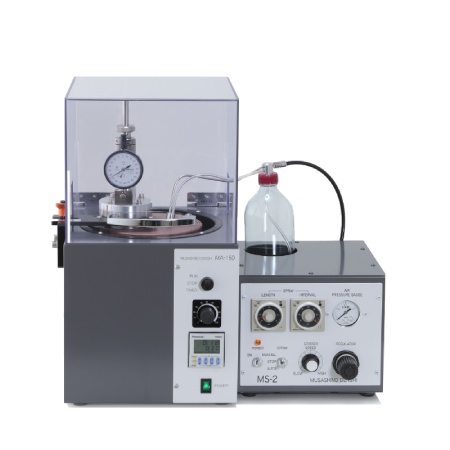

| MA-150 |

|

Size | W240mm×D285mm×H441mm (W9.4″×D11.2″×H17.3″) |

| Weight | 12kg (27.5lbs) | |

| Platen Diameter | 150mm (5.9″) | |

| Rotation Speed | 0rpm – 180rpm | |

| Control Panel | Analog Controller | |

| Timer | Digital Timer (MAX. 99m 59s) | |

| Motor Type | Speed Control Motor 40W | |

| Power Input | AC 100V | |

| Ideal for making TEM samples. Holds two roller type holding units. It is designed to be installed next to SEM, EPMA, TEM, etc., so that one unit can be used for a single purpose. Automatic polishing can be performed by setting the timer and installing the MS-2 automatic abrasive spray system. It is ideal for preparation of samples with small dimensions. Various types of grinding jigs for MA-150 are available. |

||

| MA-200 |

|

Size | W390mm×D510mm×H210mm (W15.3″×D20″×H8.2″) |

| Weight | 25kg (55.1lbs) |

|

| Platen Diameter | 200mm, 203mm (7.8″, 8″) | |

| Rotation Speed | 0rpm – 200rpm | |

| Control Panel | Analog Controller | |

| Timer | Digital Timer (MAX. 99m 59s) | |

| Motor Type | Speed Control Motor 120W | |

| Power Input | AC 100V | |

| With the timer function of the MA-200 and the MS-2 automatic sprayer, automatic polishing work can be performed easily. It is easy to obtain a flatness of λ/10 or less and a surface roughness of 0.01μm or less. No edge sagging and no inclusions falling off, making it ideal for EPMA evaluation. Suitable for cross-sectional and inclined polishing of IC and end-face polishing of optical crystal such as LN. Various polishing jigs and attachments for MA-200 are available. |

||

| MA-200e |

|

Size | W390mm×D485mm×H533mm (W15.3″×D19″×H20.9″) |

| Weight | 25kg (55.1lbs) |

|

| Platen Diameter | 200mm, 203mm (7.8″, 8″) | |

| Rotation Speed | 0rpm – 200rpm | |

| Control Panel | LCD Panel Controller | |

| Timer | Digital Timer (MAX. 99h 59m 59s) | |

| Motor Type | Speed Control Motor 120W | |

| Power Input | AC 100V | |

| We have improved the drive system and the rigidity of the machine to reduce vibration and noise in the polishing process. The digital operation using the LCD touch panel improves operability. A wide variety of recipes for polishing processes can now be centrally managed on the touch panel. The jigs and attachments of the previous generation MA-200D can continue to be used. Additional specifications such as interlock mechanism, leakage breaker, emergency stop switch, etc. can be changed in a short period of time. Various types of jigs and attachments for MA-200e are available. |

||

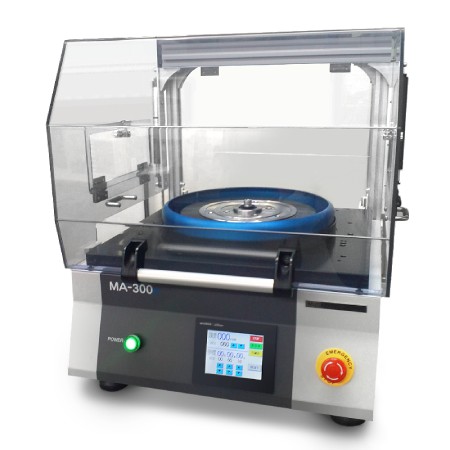

| MA-300e |

|

Size | W540mm×D570mm×H335mm (W21.2″×D22.4″×H13.1″) |

| Weight | 71kg (156.5lbs) |

|

| Platen Diameter | 300mm (11.8″) | |

| Rotation Speed | 0rpm – 200rpm | |

| Control Panel | LCD Panel Controller | |

| Timer | Digital Timer (MAX. 99h 59m 59s) | |

| Motor Type | Speed Control Motor 200W | |

| Power Input | AC 100V | |

| We have improved the drive system and the rigidity of the machine to reduce vibration and noise in the polishing process. Excellent precision (+/-1µm) for a mass production unit. Can hold up to three six station holders for polishing 18 specimens at once. We have improved the drive system and the rigidity of the machine to reduce vibration and noise in the polishing process. The digital operation using the LCD touch panel improves operability. This system is ideal for polishing samples as large as 3″ or 4″. There are three locations where the automatic holding unit can be installed, which further improves work efficiency. The oscillating device not only maintains the flatness of the grinding machine, but also improves the grinding accuracy. Additional specifications such as interlock mechanism, leakage breaker, emergency stop switch, etc. can be changed in a short period of time. Various types of jigs and attachments for MA-300e are available. |

||

| MA-400e |

|

Size | W620mm×D650mm×H345mm W24.4″×D25.5″×H13.5″ |

| Weight | 84kg (185.1lbs) |

|

| Platen Diameter | 381mm (15″) | |

| Rotation Speed | 0rpm – 200rpm | |

| Control Panel | LCD Panel Controller | |

| Timer | Digital Timer (MAX. 99h 59m 59s) | |

| Motor Type | Speed Control Motor 400W | |

| Power Input | AC 200V (3-Phase) | |

| Powerful machine for high speed polishing of specimens up to 150mm Can hold up to three, six station holders for polishing 18 specimens at once. We have improved the drive system and the rigidity of the machine to reduce vibration and noise in the polishing process. The digital operation using the LCD touch panel improves operability. A wide variety of recipes for polishing processes can now be centrally managed on the touch panel. The spindle is directly mounted on the upper surface plate with high-precision grinding finish, which improves the grinding accuracy. High-precision angular bearings are used in the spindle to achieve a surface runout accuracy of ±10µm or less. The brushless DC motor does not change the rotation speed due to load fluctuation, which enables higher precision polishing work. Additional specification changes can be made in a short period of time to options such as interlock mechanisms, leakage breakers, emergency stop switches, etc. to ensure safe operation. By combining the automatic polishing holding unit and various sample holders, it is possible to perform a variety of precision polishing operations such as polishing electronic materials, electronic components, ceramics, and metal materials; preparation of data for TEM, SEM, and SIMS analysis; and X-ray orientation grinding. |

||

| MM-200 |

|

Size | W620mm×D650mm×H345mm W24.4″×D25.5″×H13.5″ |

| Weight | 20kg (44lbs) |

|

| Platen Diameter | 200mm, 203mm (7.8″, 8″) | |

| Rotation Speed | 0rpm – 330rpm | |

| Control Panel | Analog Controller | |

| Timer | None | |

| Motor Type | Speed Control Motor 90W | |

| Power Input | AC 100V | |

| Easy-to-use hand polishing device for sample preparation. Can operate reverse rotation. This is the most suitable machine for easy polishing. Hand polishing can be done while pouring water into the machine. The Φ203mm aluminum grinding machine and retaining ring are included as standard equipment, and by replacing the water-resistant paper, you can perform grinding work with various counts. |

||

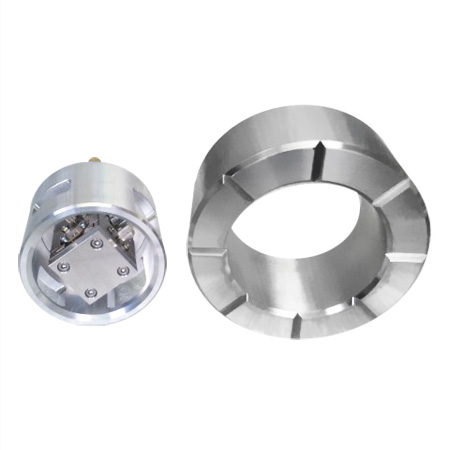

Auto Lapping Units

| Model | Feature |

|

Rollers support the holder, and assist in the smooth rotation of the holder. |

| Roller Style Unit | |

|

The tip of the unit inserted into the bearing helps the holder to rotate smoothly. |

| Pantograph Style Unit | |

|

This unit is ideal for quantitative control of the polishing process. |

| Forced Drive Unit | |

|

This unit is ideal for maintaining the flatness of the grinding and polishing plates. |

| Titubation Unit | |

|

The unit combined Forced Drive Unit and Titubation Unit. |

| Forced Drive & Titubation Unit |

Sample Holders

| Model | Feature |

|

Precision polishing sample holder for accurate wafer polishing. Can hold wafer size 2″, 3″, 4″ dia and control polishing amount. Polishing amount setting accuracy : +/- 3µm Parallelism accuracy : +/- 1µm |

| Vacuum Holder | |

|

Precision polishing sample holder for Si wafer, InP Compound semiconductor and so on. Can hold gluing plate 52mm, 68mm, 78mm dia and control polishing amount. Polishing amount setting accuracy : +/- 3µm Parallelism accuracy : +/- 1µm |

| High Precision Holder | |

|

Suitable for sample preparation for TEM. Can hold gluing plate 40mm and 52mm dia. Polishing amount setting accuracy : +/- 5µm Parallelism accuracy : +/- 3µm |

| TEM Holder | |

|

Can hold gluing plate 52mm, 78mm dia and control polishing amount. |

| Adjustment Holder | |

|

Can perform various polishing by changing attachments. Gluing plate attachment : 40mm×30mm (1.5″×1.1″) Angle plate attachment : 40mm×20mm (1.5″×0.7″) 5-degree Clamping attachment : W16mm×H16mm×t4mm (W0.6″×H0.6m”×t0.1″) |

| Multipurpose Holder | |

|

After attaching the sample to the gluing plate with hot wax, perform polishing work. Can hold plate 52mm, 78mm, 107mm and 130mm dia. |

| Gluing Holder | |

|

Can hold embeded sample 25mm, 30mm and 40mm dia. 3 to 6 hangings for Roller and Pantograph style unit. |

| Plug-in Holder | |

|

Can hold platelike sample 50mm×5mm (1.9″×0.2″) , 80mm×5mm(3.1″×0.2″). Option : Optical fiber polishing specification |

| Clamping Holder | |

|

By using an attachment to be attached to the rail of the X-ray Laue camera, it is possible to perform polishing work by correcting the orientation of the two axes. |

| 2-axis Holder |

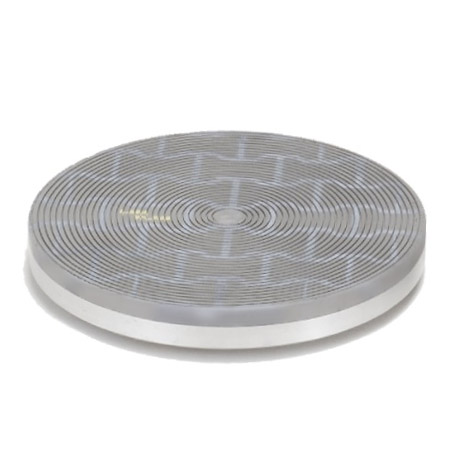

Grinding And Polishing Platens

| Model | Materials | Grit Size | Process |

|

Diamond Resin bond |

#80 to #4000 | Preliminary Grinding |

| Diamond Platen | |||

|

Silicon Carbide | P60 to P2000 | Preliminary Grinding |

| SiC Paper | |||

|

Diamond Resin bond |

#80 to #1200 | Rough Grinding |

| CAMEO DISK Platinum | |||

|

Copper Cast Iron |

45μm to 9μm | Preliminary Grinding |

| NL Blue | |||

|

Copper Cast Iron |

15μm to 3μm | Middle Polishing |

| NL Green | |||

|

Copper Cast Iron |

< 3μm | Final Polishing |

| NL Yellow | |||

|

Copper |

6μm to 2μm | Final Polishing |

| MF Copper | |||

|

Aluminium Oxide | 3μm to 1/2μm | Final Polishing |

| HP Ceramic | |||

|

Tin Lead Plastic |

3μm to 1/4μm | Final Polishing |

| HP TX | |||

|

Plastic | 1μm to 1/2μm | Final Polishing |

| MF Plastic | |||

|

Tin | 1μm to 1/10μm | Final Polishing |

| MF Tin | |||

|

Natural Fiber Synthetic Fiber |

6μm to 3/200μm | Final Polishing CMP |

| Polishing Cloth | |||

|

Special Polyurethane | 1/25μm to 3/200μm | CMP |

| CMP Pad |

Platen Conditioner

| Model | Feature |

|

Be used to quickly repair the flatness of platens. Diamond powder size : #140 |

| Diamond Ring | |

|

Can measure the flatness of platens. |

| Dial Gauge | |

|

Can repair the flatness of the platens by using a diamond bite tool. Reproducible and easy to install, no difference in grinding results due to different operators. |

| Bite System |

Abrasives

| Model | Materials | Grit Size | Process |

|

Diamond Water Oil |

45μm to 1/10μm | Preliminary Grinding Middle Polishing Final Polishing |

| Diamond Slurry | |||

|

Diamond Water |

12μm to 1μm | Preliminary Grinding Middle Polishing Final Polishing |

| Diamant Liquids | |||

|

Aluminum Oxide (White) |

#240 to #30000 | Preliminary Grinding Middle Polishing Final Polishing |

| WA Abrasive | |||

|

Silicon Carbide (Green) |

#240 to #30000 | Preliminary Grinding Middle Polishing Final Polishing |

| GC Abrasive | |||

|

Aluminum Oxide (High Purity) |

1/20μm | Final Polishing |

| Aluminum Liquids | |||

|

Cerium Oxide | 2.1μm | Middle Polishing |

| Cerium Oxide Liquids | |||

|

Colloidal Silica | 13/400μm to 3/200μm | CMP |

| Colloidal Silica Liquids | |||

|

Silicon Dioxide | 1/25μm | CMP |

| Chemical Liquids |

Automatic Sprayer

| Model | Feature |

|

This apparatus automatically agitates the liquid diamond. Can control interval and length of spraying. |

| MS-2 |

| Thank you for reading this to the end. |

Musashino Denshi, INC.

1-17-18 kichijoji higashi, Musashino, Tokyo, 180-0002 Japan

E-mail: info@musashino-denshi.co.jp

Copyrights © 2021 Musashino Denshi, INC. All Rights Reserved.