BLADE SAWS

The MPC series of precision blade saws features a step-feed function and a balanced weight cutting system to ensure sample-friendly cutting. In addition, the compact and desktop type machine makes it easy to cut and relocate the machine in a small space. We can offer a variety of jigs to suit your specimen, such as waxed specimens or resin-embedded specimens. In addition, the Lauer attachment and custom-made jigs can be used for any cutting scene.

Blade Saws

| MPC-200e |

|

Size | W472mm×D474mm×H440mm (W18.5″×D18.6″×H17.3″) |

| Weight | 51kg (112.4lbs) | |

| Blade Diameter | 75mm – 205mm (2.9″ – 8″) | |

| Rotation Speed | 100rpm – 4000rpm | |

| Feed Rate | 0mm/min – 100mm/min (0”/min – 3.9”/min) |

|

| Control Panel | LCD Panel Controller | |

| Motor Type | Single‐phase Motor 200W | |

| Power Input | AC 100V | |

| The high-precision slide mechanism of the worktable allows for parallel cutting of 100 μm. The cutting position can be determined in 10 µm increments with a moving mechanism that employs a micrometer. The motor-driven feed mechanism can be used to set stepless feed in the range of 0 mm to 100 mm/min. The worktable can be moved automatically or manually. The step mechanism makes it easy to cut iron-based materials that are easy to bite into the grindstone. A goniometer is also available as an option, which can be cut directly after the crystal orientation is determined by X-ray diffraction. |

||

| MPC-130 |

|

Size | W285mm×D263mm×H350mm (W11.2″×D10.3″×H13.7″) |

| Weight | 7kg (15.4lbs) |

|

| Platen Diameter | 75mm – 127mm (2.9″ – 5″) | |

| Rotation Speed | 0rpm – 640rpm | |

| Feed Mechanism | None | |

| Control Panel | Analog Controller | |

| Motor Type | Speed Control Motor 25W | |

| Power Input | AC 100V | |

| The cutting method with low speed rotation and balance weight prevents the sample from being damaged. The small size and light weight of the device makes it easy to move the device in a small space. The cutting position can be determined in increments of 10 µm by using a moving mechanism using a micrometer. The interlocking cover enables safe and secure cutting work. |

||

Blades

| Model | Feature |

|

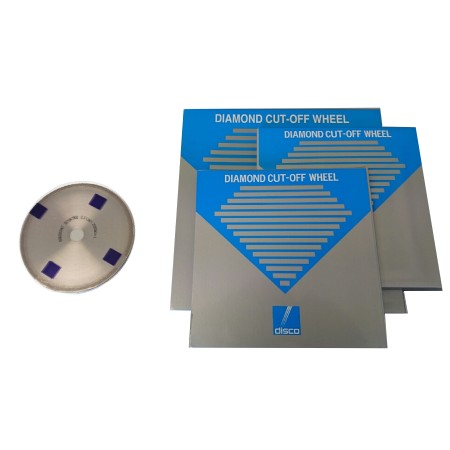

This blade can cut a wide range of materials such as metals, ceramics, and glass. This is a grinding wheel with artificial diamonds bonded to the periphery of the blade with a metal bond. [Purpose] All Materials |

| Diamond Blade | |

|

It is an abrasive material of alumina. Mainly used for cutting iron-based materials such as steel and hardened steel. [Purpose] Special steel products |

| Aluminum Blade | |

|

This is a silicon carbide abrasive material. Mainly used for cutting hard and brittle materials such as stone and cast iron. [Purpose] Non-ferrous metals in general |

| Carbide Blade |

Expendables

| Model | Feature |

|

The cooling effect improves cutting accuracy and prevents the grinding wheel from burning. The alkaline component of the cutting fluid prevents rust and corrosion of samples and equipment. |

| Cutting Fluid | |

|

The sample is glued to the baked plate and cut using a chuck jig. It is used for cutting with a precision blade saw or diamond wire saw, and the sample is cut by the method of putting the blade slightly into the bare plate. It is easy to clean the wax and other adhesives. |

| Porous Sheet | |

|

High adhesive strength allows for high-precision processing. It can be cleaned with alkaline and various organic solvents. |

| Shift Wax |

| Thank you for reading this to the end. |

Musashino Denshi, INC.

1-17-18 kichijoji higashi, Musashino, Tokyo, 180-0002 Japan

E-mail: info@musashino-denshi.co.jp

Copyrights © 2021 Musashino Denshi, INC. All Rights Reserved.